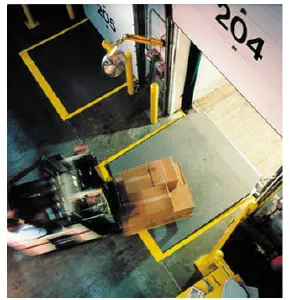

Efficiency at the loading dock can significantly influence the overall productivity of

warehouse operations. Edge of Dock levelers (EODs) have become instrumental in streamlining the loading and

unloading process. As a cost-effective and space-saving solution, EODs provide an essential service for warehouses

managing a high volume of goods. They offer a reliable platform to bridge the gap between different heights of dock

doors and transportation vehicles.

Understanding Edge of Dock Levelers

Edge of Dock levelers are mounted on the dock face and provide a slight extension for

bridging the gap between the dock and the truck bed. Designed for applications where there isn't a significant

difference in height between the warehouse floor and the vehicle, EODs efficiently facilitate the safe transition of

goods, with a working range typically around plus or minus three inches from dock level.

Types and Operation Modes

EOD levelers come in mechanical and hydraulic versions:

Mechanical EOD Levelers: These involve a manual activation process, wherein a lever or bar

is used to lower the platform into place. The mechanical spring-action system requires minimal effort and no

electricity, making it an energy-efficient option.

Hydraulic EOD Levelers: Operated with the push of a button, these levelers use a hydraulic

system to raise and lower the lip. They provide an easy-to-use, low-effort solution for frequent loading and

unloading needs.

Both types incorporate a hinged lip to smoothly transfer goods from the dock to the trailer

bed, ensuring that forklifts and pallet jacks can move across securely.

The Integral Role of EOD Levelers in Warehouses

The primary role of Edge of Dock levelers is to optimize the safety and speed of loading

activities. They offer several compelling benefits for warehouse operations:

Improved Productivity: By ensuring a smooth transition from dock to truck, EODs reduce

loading times, contributing to more efficient turnover and faster fulfillment of shipping and receiving

processes.

Enhanced Worker Safety: EOD levelers minimize the risk of injuries related to trips, slips,

or falls. By providing a consistent and level pathway, they significantly reduce the occurrence of accidents

that can impair health and productivity.

Equipment Protection: By minimizing the drop or rise that forklifts must negotiate, EOD

levelers prevent premature wear and tear on this costly equipment and avoid potential damage to goods during

transit.

Streamlined Space Usage: Unlike full-size dock plates or pit-style levelers, EODs require

less space and construction modification, making them ideal for warehouses with limited space or those that

cannot feasibly install larger equipment.

Selecting the Right EOD Leveler for Your Warehouse

Choosing the best Edge of Dock leveler for your warehouse depends on several factors:

Dock Activity: Assess the frequency and volume of your dock traffic. For high-traffic docks,

hydraulic EODs may offer the speed and ease of operation needed, whereas mechanical EODs might suffice for

docks with lower volumes.

Vehicle Compatibility: Consider the types of vehicles that service your dock. EODs are

suitable for standard truck heights; however, if there's considerable variation, a different solution might

be necessary.

Load Capacity: Ensure that the EOD leveler can handle the weights typical of your operation.

Overloading can lead to equipment failure and safety hazards.

Installation and Integration

Proper installation is fundamental to the functionality of Edge of Dock levelers. A

professional installation ensures that the EOD is securely attached to the dock face and operates as intended.

Integration with existing dock systems, such as dock seals or bumpers, can enhance the efficiency and safety of the

loading area further.

Maintenance and Care

Regular maintenance can extend the lifespan of EOD levelers and avoid pauses in warehouse

operation due to equipment failure. This includes routine inspections, lubrication of moving parts, and immediate

attention to any repair needs. Training staff on the correct operation and safety procedures is also vital.

Cost-Efficiency and ROI

When considering the cost of EOD levelers, weigh the initial investment against the

potential return. Reduced worker injury, faster turnaround times, and lower equipment maintenance costs contribute

to a quick recoupment of the purchase and installation expenses, making EODs a wise investment for many warehouse

facilities.

The Future of EOD Levelers

As warehouses adapt to evolving logistics technology and automation trends, the design and

functionality of EOD levelers will also advance. Anticipate future models to offer greater adjustability, enhanced

control systems, and improved integration with warehouse automation platforms.

Edge of Dock levelers are a pivotal component in contemporary warehouse logistics, offering

a blend of safety, efficiency, and space economy. As the demand for swift and secure loading operations continues to

grow, the relevance and implementation of EOD levelers will only become more pronounced. With careful selection,

installation, and maintenance, these devices can provide lasting benefits to warehouse operations, ensuring a

streamlined workflow that keeps pace with the demands of modern commerce.

Are you ready to ramp up efficiency and safety on your loading docks? Reach out to a

trusted provider of warehouse door needs, Industrial Door Company of Chicago, to find out how Edge of Dock levelers

can revolutionize your loading procedures, optimize dock performance, and drive your logistics operation forward.