In the fast-paced world of logistics and distribution, the efficiency of a warehouse's

loading dock operation can significantly impact overall productivity. Mechanical dock levelers play an essential

role in ensuring a smooth transition of goods between warehouse floors and transportation vehicles. This article

provides a comprehensive overview of mechanical dock levelers, their functionality, benefits, and considerations for

businesses looking to optimize their loading dock capabilities.

What are Mechanical Dock Levelers?

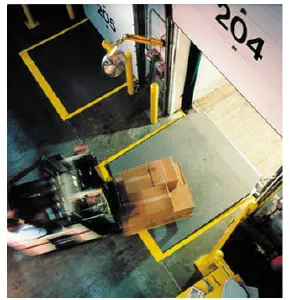

Mechanical dock levelers are devices designed to bridge the gap and height difference

between a warehouse dock and the bed of a freight truck. They enable a safe and efficient path for forklifts and

pallet jacks to move products in and out of trailers. Mechanical levelers are operated manually, typically using a

pull-chain that activates a spring mechanism to raise the leveler into position. Once extended, the leveler plate

can be walked down onto the truck bed, providing a sturdy platform for loading activities.

How Mechanical Dock Levelers Function

The operation of mechanical dock levelers is relatively straightforward, which contributes

to their popularity in many industrial settings:

Activation: The dock leveler is activated by pulling a chain that releases a spring-loaded

mechanism.

Raising: The stored energy in the springs lifts the leveler's ramp above the dock height.

Positioning: The operator physically walks the leveler's lip onto the truck bed to create an

even loading surface.

Use: With the leveler in place, materials can be safely moved onto and off the truck.

Storage: After use, the leveler is returned to its stored position, flush with the dock

floor for unobstructed dock access.

Advantages of Mechanical Dock Levelers

Mechanical dock levelers offer a range of benefits that make them an attractive option for

many businesses:

Cost-Effectiveness: They are generally less expensive to install and maintain than their

hydraulic or air-powered counterparts, making them a practical, budget-friendly solution for many

facilities.

Reliability: With fewer moving parts and less reliance on power sources, mechanical levelers

are highly reliable and less prone to failure.

Simplicity: The straightforward operation of mechanical levelers makes them easy to use with

minimal training.

Maintenance: They require relatively basic maintenance routines, focusing mainly on spring

tension adjustments and lubrication.

Durability: Built to withstand heavy use, mechanical docks can have a long lifespan when

properly maintained.

Choosing the Right Mechanical Dock Leveler

When selecting a mechanical dock leveler, consider several factors:

Load Capacity: It's critical to choose a leveler that can support the maximum weight of the

loads it will carry.

Dock Frequency: Assess how often trucks dock at your facility to determine the durability

needed from a leveler.

Compatibility: Ensure the leveler can accommodate the range of truck heights and types that

visit your dock.

Environmental Factors: If your loading dock faces extreme weather, make sure the leveler is

equipped with appropriate materials and coatings to withstand the conditions.

Maintenance and Operation Per Best Practices

Mechanical dock levelers are robust, but they still require regular maintenance to function

optimally. A typical maintenance routine includes cleaning debris from the pit and under the platform, lubricating

pivot points, and checking the integrity of springs and hold-down mechanisms.

Proper operation is also crucial to the longevity and safe use of mechanical levelers.

Operators should be trained in safe handling procedures, including how to correctly position the leveler and secure

it during loading and unloading.

Safety Considerations for Mechanical Dock Levelers

Safety is paramount in the operation of any dock equipment. Mechanical levelers should be

equipped with safety features such as toe guards, side guards, fall protection systems, and non-slip surfaces.

Additionally, regular inspections should be conducted to ensure these features are functional and intact.

The Role of Mechanical Dock Levelers in Modern Warehousing

In today's warehouses, where speed and efficiency are essential, mechanical dock levelers

continue to serve as reliable and economical solutions for steady and predictable dock operations. They are

particularly well-suited for businesses with consistent truck sizes and volumes, where the additional investment in

hydraulic systems may not be justified.

Innovation in Mechanical Dock Levelers

While mechanical dock levelers have a traditional design, innovation in materials and

safety features has kept them relevant in the industry. Enhanced durability, improved ergonomic designs, and

advancements in safety components ensure that mechanical levelers remain a competitive choice for modern facilities.

Mechanical dock levelers are an integral component of a well-run loading dock, offering

reliability, durability, and cost-effectiveness. While they may not have the automated features of hydraulic models,

their simplicity and ease of maintenance make them a compelling choice for many operations.

In the logistics and warehousing industry, where the bottom line and safety are critical,

the value of a well-chosen and well-maintained dock leveler cannot be underestimated. Mechanical dock levelers stand

out as a proven, steadfast solution, contributing to the seamless transfer of goods and the continued success of

businesses worldwide. As technology advances and operational needs evolve, mechanical dock levelers will undoubtedly

remain a staple in the industry, continuing to reconcile the timeless demands for operational efficiency and

workplace safety.

Contact the sales department at Industrial Door Company for all of your warehouse door

needs.